High-Q superconducting resonators fabricated in an industry-scale semiconductor-fabrication facility

2025-10-30 14:03

1828 浏览

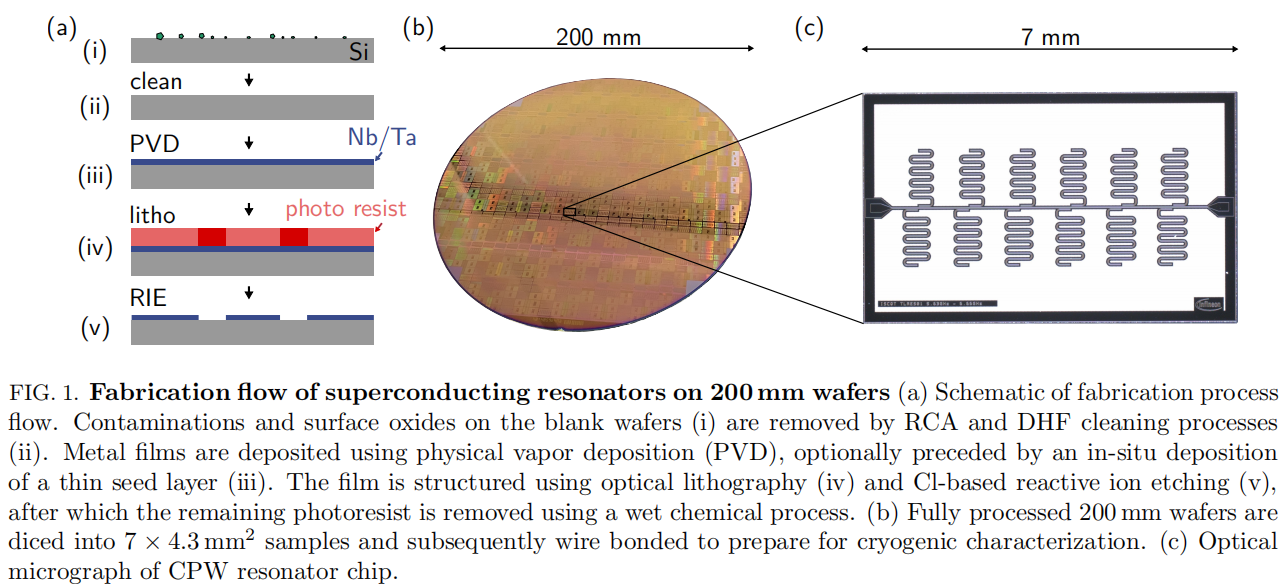

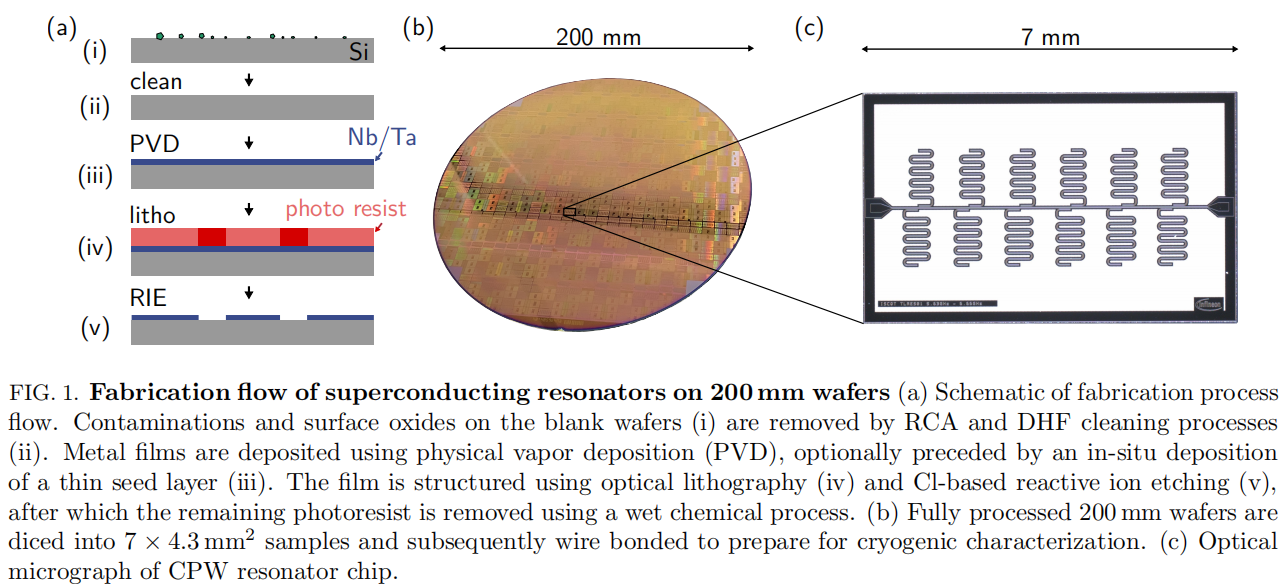

Universal quantum computers promise to solve computational problems that

are beyond the capabilities of known classical algorithms. To realize

such quantum hardware on a superconducting material platform, a vast

number of physical qubits has to be manufactured and integrated at high

quality and uniformity on a chip. Anticipating the benefits of

semiconductor industry processes in terms of process control, uniformity

and repeatability, we set out to manufacture superconducting quantum

circuits in a semiconductor fabrication facility. In order to set a

baseline for the process quality, we report on the fabrication of

coplanar waveguide resonators in a 200 mm production line, making use of

a two-layer superconducting circuit technology. We demonstrate high

material and process quality by cryogenic Q-factor measurements

exceeding

Link to the article is here.