Low loss lumped-element inductors made from granular aluminum

2024-11-24 19:21

2831 浏览Abstract: Lumped-element inductors are an integral component in the circuit QED toolbox. However, it is

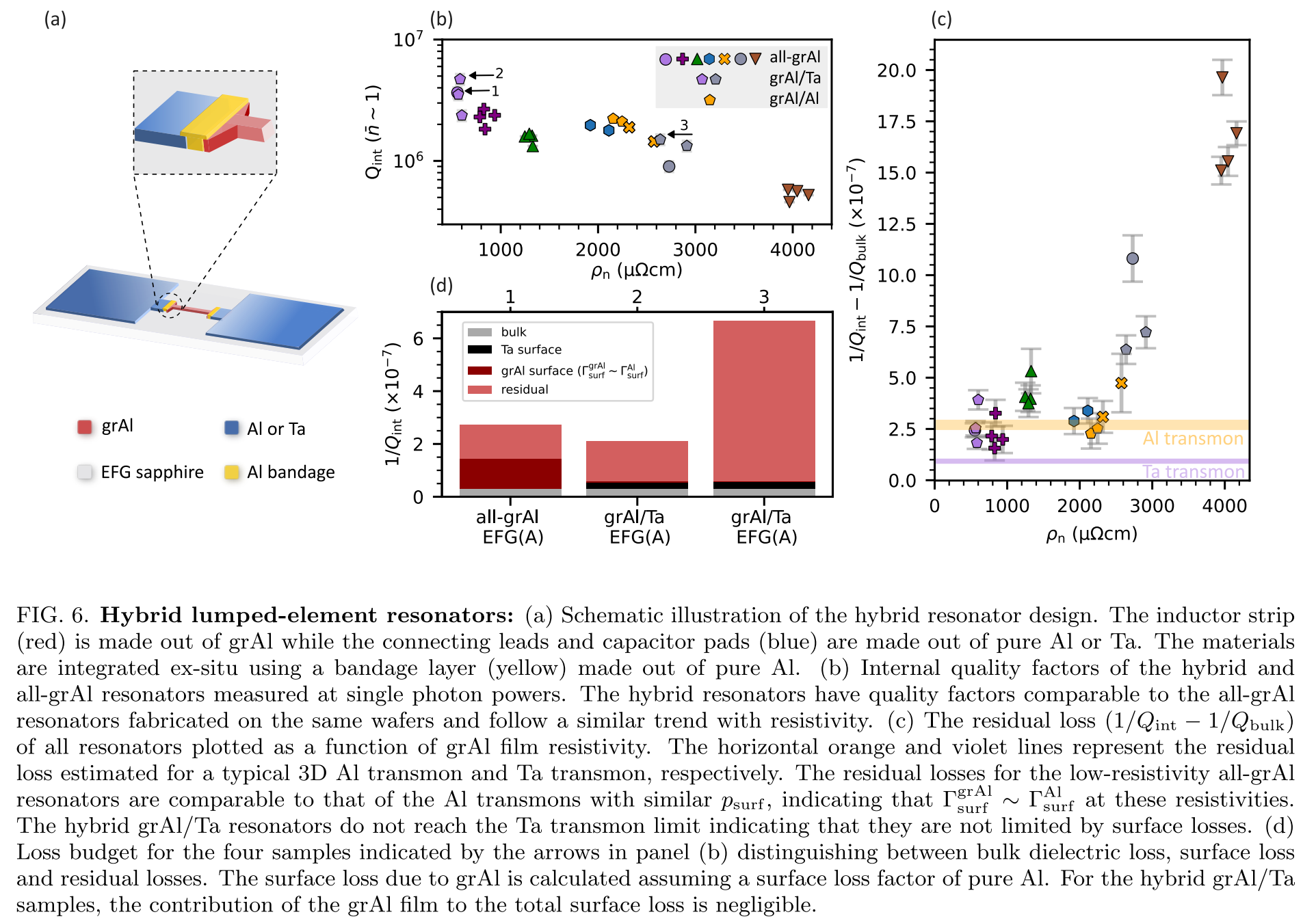

challenging to build inductors that are simultaneously compact, linear and low-loss with standard approaches that either rely on the geometric inductance of superconducting thin films or on the kinetic inductance of Josephson junctions arrays. In this work, we overcome this challenge by utilizing the high kinetic inductance offered by superconducting granular aluminum (grAl). We demonstrate lumped-element inductors with a few nH of inductance that are up to 100 times more compact than inductors built from pure aluminum (Al). To characterize the properties of these linear inductors, we first report on the performance of lumped-element resonators built entirely out of grAl with sheet inductances varying from 30 − 320 pH/sq and self-Kerr non-linearities of 0.2−20 Hz/photon. Further, we demonstrate ex-situ integration of these grAl inductors into hybrid resonators with Al or tantalum (Ta) capacitor electrodes without increasing total internal losses. Interestingly, the measured internal quality factors systematically decrease with increasing room- temperature resistivity of the grAl film for all devices, indicating a trade-off between compactness and internal loss. For our lowest resistivity grAl films, we measure quality factors reaching 3.5×106 for the all-grAl devices and 4.5 × 106 for the hybrid grAl/Ta devices, similar to state-of-the-art quantum circuits. Our loss analysis suggests that the surface loss factor of grAl is similar to that of pure Al for our lowest resistivity films, while the increasing losses with resistivity could be explained by increasing conductor loss in the grAl film.

CONCLUSIONS: In summary, using the high kinetic inductance of grAl, we have realized an inductor that is simultane- ously lumped-element, linear and low-loss. We have fabricated ∼ 90nm thick grAl films with sheet inductances of 30−320 pH/sq to implement grAl inductors with several nH of inductance. To validate their utility in high- coherence circuits, we have characterized a total of 20 all- grAl resonators. Their low self-Kerr non-linearity rang- ing between 0.2 and 20 Hz/photon makes them signifi- cantly more linear than conventional arrays of Josephson junctions of similar length. We find that our data is well described by an effective circuit model that treats the grAl inductor as a 1D array of effective JJs. We estimate the size of these effective junctions to be around 10 - 30 nm, corresponding to a large number of JJs even for micrometer sized elements.

Further, by taking advantage of the 3D transmon geometry and the low loss environment provided by our coaxial tunnel package, we demonstrate internal quality factors that are well beyond 106. Since our mea- surements are primarily sensitive to losses related to the grAl film and the substrate, we uncover a correlation between the normal-state resistivity of grAl and microwave losses. This implies a trade-off between quality factor and resistivity of the grAl film, suggesting that resistivity is an important design consideration for grAl lumped- element inductors and grAl devices in general. A similar degradation of the internal quality factor in the single- photon regime with increasing sheet resistance has also been observed in some other high kinetic inductance ma- terials like NbN and amorphous InO . Interestingly, our analysis indicates that our lowest resistivity grAl resonators have surface losses comparable to 3D Al transmons.

Furthermore, we have demonstrated high quality factors in hybrid resonators that integrate these high- impedance grAl inductors with low-impedance Al or Ta capacitors. Our method of using a dedicated Al bandage layer to make the contact allows grAl to be compatible with a variety of fabrication processes. Since we observe the same trend with resistivity in all devices, we suspect that increasing losses are caused by increasing conductor losses in the grAl strip. These findings motivate future studies that can uncover the microscopic mechanisms that contribute to losses in grAl films and the contacts in hybrid devices.